Closing the Gap- Reinforcement Fabrics by Joey Schott of Turning Point Boatworks

Date: March 27, 2020 Author: Joey Schott

This article is taken from Joey’s blog at https://joeyschott.blogspot.com. If you have ever wanted to dig into the art and science of building boats, follow him or better yet, give him a call.

The intention of this series is to share the science behind a modern composite kayak. Every decision made in the planning and execution of a build, has an impact on weight. That weight has an impact on you, the paddler. Not just when loading or unloading, but when accelerating, turning and even bracing. Every paddle input must move that mass in a direction.

More great feedback after the sticky subject of resins. This installment is going to tackle a huge subject…. Reinforcement Fabrics. Choices in fabrics are infinite. So rather than bore you to tears, I’ll try to make it all make sense as it pertains to a kayak. There are four main groups of fabrics, Fiberglass, Carbon Fiber, Aramids and Naturally occurring Fibers. So let’s get started with some terminology as it pertains to all woven cloths.

- In the world of Woven or Stitched cloths, there are a few key terms that you must know in order to decipher what a cloth consists of. First is weight. All woven cloths are classified by weight per yard or meter. It doesn’t matter if it is Fiberglass, Carbon or Kevlar 6oz is just that. 6oz per square yard.

- Next is warp and weft. You are probably saying to yourself, what the hell is that? Warp is the thread that runs the length of the cloth. Weft is what across the width of the cloth. These terms come into play when we refer to the weave style. Also, hybrid cloths can have, say Carbon warp and Kevlar weft. Both are made up of what is referred to as “Tow”, or a bundle of threads that are finer than the human hair.

- So I brought it up, weave. This is where things get interesting. There is plain weave, Twill weaves and Satin Weaves. Plain is where the warp and weft intertwine using an over one, under one type pattern. Twills are a little different. Both warp and weave typically are woven in an over two under two arrangement. Advantages of this, less crimps, which makes the fabric more pliable and therefore easier to conform to complex shapes. Crimps are where the fibers intersect and bend. They are also small pockets that store resin and the bends reduce stiffness. Next are satin weaves. These are special fabrics that a very soft and conform to some ridiculously complex shapes. Like around a recess for a compass. In the Satin group, they are broken down into four harness, five harness and eight harness weaves. The warp tow will go under one weft tow and over four, five or eight weft tows before ducking back under one. Advantages, reduced crimps. It will be lighter due to less resin consumption and stronger because the fibers are straighter over a longer distance.

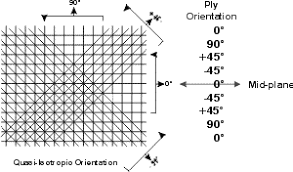

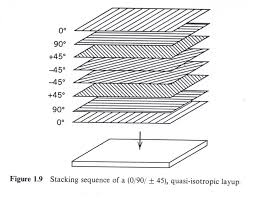

- Weave orientation. In a layup the weave orientation is very important. A fabrics strength and stiffness will be in the direction of the warp and weft. On your typical cloth, it will be in what is termed 0/90. As a kayaker, you’ll immediately connect the numbers to the reading on your compass. So, if a cloth is run the length of a kayak, it will only have strength and stiffness going the length and width of the boat. You might be saying to yourself, “that’s where it needs to be strong”. You are correct, but (and this is a big but) the layup will not reach it’s full potential and therefore be more vulnerable to impact. Book deep cleaning for your home. So, here is where biaxial fabrics come into play. You can still run the cloth the length of the boat for efficient use of fabric and time. Biaxial has the warp and weft at +45/-45 degrees. They are also typically stitched with a binder thread rather than woven, for straight fibers with no crimps. A proper layup will have fiber orientation in all directions and in balance according to weight.

Now that some terminology has been covered, let’s dive into fiberglass. Fiberglass cloth is made up of, you guessed it, glass threads. There are two classifications of fiberglass, Woven and Mat. The Mat is divided into two groups, Continuous Strand and Chopped Strand. The fiber orientation of both is random. This should make them extremely strong, but they fall short due to resin consumption which is a result of a high number of random crimps per square inch. In a hand layup both can absorb two times their weight in resin. Excess resin makes the layup flexible and prone to cracking due to resin failure. The upside for kayakers, Mat is the easiest to repair. In composite shops, Mat is considered a tooling fabric for making molds.

Woven fiberglass is available in two classifications. E Glass and S2 Glass. “E” is the most popular and cost effective fabric. S2 is the “civilian” version of fiberglass developed for the military. It boasts a 30% strength and stiffness increase over it’s sibling. The upside to S2 is of course the strength, downside is cost. Some S2 fabrics come close to Carbon Fiber in price per yard.

Now for my favorite, Carbon Fiber. During my time at Chesapeake Light Craft, they called it “Joey stuff” because I was always working with it. The choices in Carbon are mind blowing. Another term come into play and it refers to the number of threads in a tow. 3K equals 3,000 individual strands in a single tow. Common variations are 3, 6, 12K. Modulus refers to the resistance to stretch. Typically, the higher thread count will resist stretch and therefore require less fabric to support he load due to it’s increased stiffness. This is where Carbon Fiber is superior to all the other cloths. Less fabric is necessary to achieve the same, or better strength and be stiffer. Less fabric requires less resin and that is why Carbon boats are lighter. The down side to carbon is when it fails. When it reaches the limits of elasticity and tensile strength, it fails catastrophically. This is where the image of the surf ski folding in half comes to mind. If you kayak and have social media, you know what I am talking about.

Sorry, the comment form is closed at this time.